Versatile Product Handling: Discover Multipurpose Screener for Sale

Versatile Product Handling: Discover Multipurpose Screener for Sale

Blog Article

Discover the Top Screener Devices for Effective Recycling Processes

As the need for reusing proceeds to grow, markets are regularly seeking ways to enhance their recycling processes and optimize efficiency. From shaking screeners to disc screeners, numerous types of tools are offered to guarantee the reliable separation of products.

Vibrating Screeners

Vibrating screeners are necessary equipment made use of in recycling procedures to efficiently different and classify products based on their size and make-up. These screeners play a crucial function in the reusing industry by making sure that materials are appropriately sorted and gotten ready for more processing.

Among the key functions of shaking screeners is their capability to vibrate at high rates, which aids to properly separate different kinds of products. The vibrating movement permits smaller sized particles to go through the screen while larger bits are preserved. This process makes sure that products are classified precisely, causing enhanced reusing efficiency.

Furthermore, shaking screeners are outfitted with multiple decks or layers of screens. Each deck is created to take care of specific size varieties, making it possible for the synchronised sorting of different products. This multi-deck arrangement increases the screening capacity and enhances the accuracy of material classification.

Moreover, vibrating screeners are usually geared up with different kinds of screening media, such as wire mesh, polyurethane panels, or perforated plates. The option of evaluating media depends on the particular requirements of the recycling procedure. These media alternatives offer different levels of longevity, resistance to abrasion, and ease of maintenance.

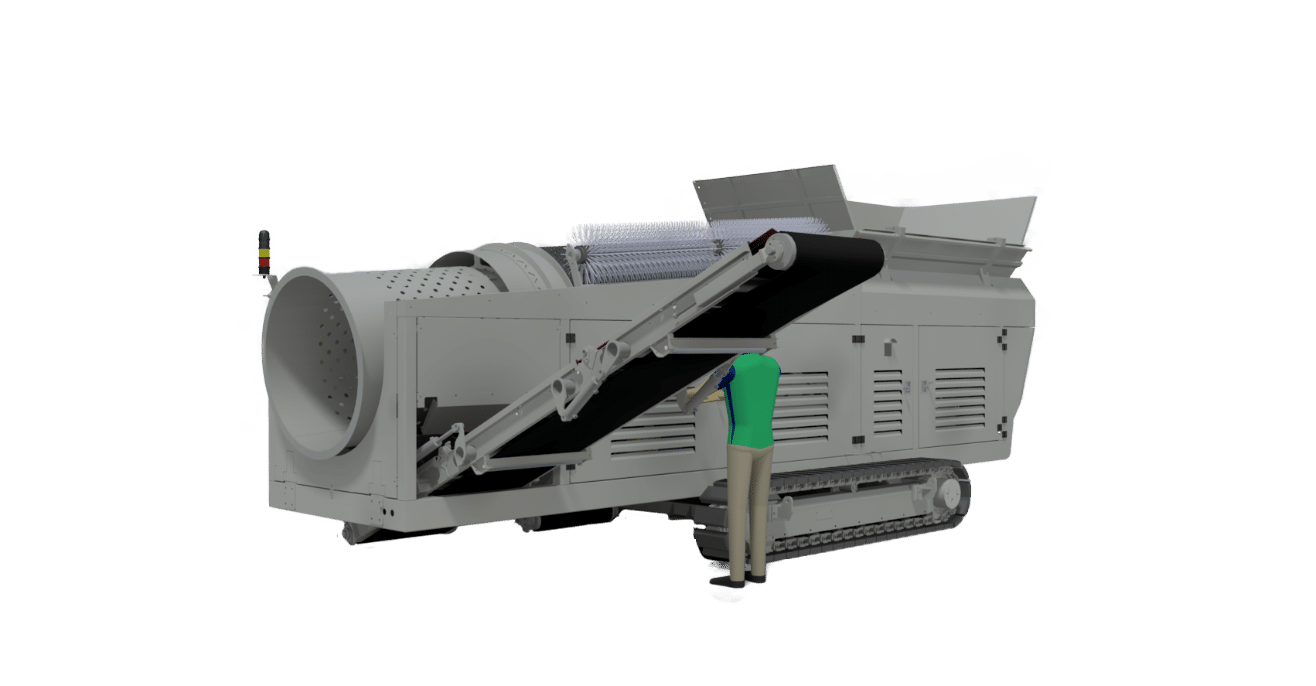

Trommel Screeners

Are you interested concerning the advantages and functions of Trommel Screeners in the recycling industry? Trommel Screeners are extremely reliable makers used in the recycling procedure to separate and arrange different products. They contain a round drum that rotates, permitting the material to be evaluated. The trommel drum is equipped with different dimensions of screens, which categorize the products based on their dimension.

Among the major advantages of making use of Trommel Screeners is their ability to manage a wide variety of products. screener for sale. They can efficiently evaluate and divide various kinds of waste, such as local solid waste, building and construction and demolition compost, particles, and biomass. This adaptability makes them a beneficial property in recycling facilities

Trommel Screeners are also known for their high throughput capability. They can refine huge quantities of material quickly and efficiently, guaranteeing a constant flow of material with the recycling process. This assists to enhance total performance and lower downtime.

Furthermore, Trommel Screeners are designed to minimize contamination. By separating materials based upon dimension, they can get rid of undesirable impurities, such as plastics, steels, and other non-recyclable products. This aids to boost the top quality of the last recycled products.

Flip Flow Screeners

Flip Flow Screeners are a sort of testing tools frequently utilized in the recycling industry to effectively separate and sort numerous products. These screeners are developed with a distinct flip flow activity that permits for efficient screening of difficult products such as damp, sticky, and fine particles.

The trick advantage of Flip Flow Screeners is their capacity to manage a variety of products with high effectiveness. They are particularly reliable in separating materials such as building and construction and demolition waste, garden compost, biomass, and community strong waste. The flip flow motion makes sure that the materials are extensively screened, avoiding clogging and optimizing throughput.

Flip Circulation Screeners are equipped with specially created polyurethane screens that have high resistance to tear and use. This makes certain a longer life-span and decreases upkeep expenses. In addition, the screens can be quickly changed or cleaned up, better enhancing the effectiveness of the screening process.

An additional significant feature of Flip Flow Screeners is their portable design, enabling them to be conveniently integrated into existing reusing systems. screener for sale. They can be made use of as standalone devices or as component of a bigger handling line, depending on the particular demands of the reusing facility

Disc Screeners

To continue our exploration of testing tools for reusing processes, we now turn our interest to Disc Screeners. Disc Screeners are very reliable equipments developed to separate products based upon their dimension and form. They are commonly used in the recycling market to kind and identify numerous kinds of waste, consisting of construction debris, organic materials, and community solid waste.

Disc Screeners contain a series of turning discs that have little openings or ports. As the product is fed onto the discs, the smaller sized particles drop via the openings while the bigger ones remain to move ahead. This splitting up process permits the efficient removal of unwanted materials and the production of click for more high-grade recyclable items.

Celebrity Screeners

Celebrity Screeners are cutting-edge testing machines that are commonly utilized in the reusing market to successfully different products based upon their dimension and form. These machines contain a rotating drum with star-shaped discs or shafts that have gaps between them. As the drum rotates, the materials are fed onto the screen, and the star-shaped discs or shafts separate them based on their size. The smaller sized products drop via the voids, while the larger products continue to move along the drum.

One of the essential advantages of making use of Celebrity Screeners is their capability to successfully separate materials of different dimensions. The star-shaped discs or shafts can be set up with different gap sizes, permitting for specific splitting up based on the desired fragment size. This makes Star Screeners perfect for reusing applications where materials require to be arranged and processed based on their details dimensions.

One more advantage of Celebrity Screeners is their high throughput capacity. These makers can refine large quantities of products in a brief amount of time, making them extremely reliable for reusing operations. The turning drum layout also helps my link to avoid product clogging, making sure continuous and nonstop handling.

In enhancement to their screening abilities, Star Screeners can likewise be geared up with additional functions such as air separation systems or magnetic separators to additionally enhance the reusing procedure. These devices are functional and can be tailored to satisfy specific recycling demands.

Conclusion

To conclude, the top screener devices for reliable recycling procedures include vibrating screeners, trommel screeners, flip circulation screeners, disc Homepage screeners, and celebrity screeners. These equipment alternatives give efficient solutions for separating and arranging various materials, assisting to boost the recycling process. By making use of these screeners, reusing facilities can improve their performance and guarantee the high quality of recycled materials.

Trommel Screeners are highly efficient machines utilized in the reusing process to separate and arrange various products. They can process large volumes of product promptly and successfully, making sure a continual circulation of material through the recycling process. By separating products based on dimension, they can get rid of undesirable contaminants, such as plastics, metals, and other non-recyclable materials. The smaller products drop via the gaps, while the larger materials continue to move along the drum.

By utilizing these screeners, recycling facilities can improve their efficiency and make certain the top quality of recycled products.

Report this page